MAXCRETE 800

CEMENT BASED TILE ADHESIVE

Description

Maxcrete 800 Tile Adhesive is a premixed grey or white powder consisting of high grade cement, graded fine

sand, premium quality synthetic resins and special additives that requires only the addition of water to form a

highly workable mortar with good bonding strength, low slump and high grab to adhere ceramic floor and wall.

Features

✓ Requires only addition of water.

✓ Excellent workability and minimal sag.

✓ Good adhesion and bonding strength

✓ Impact and water resistant.

Limitations

✓ Do not use over gypsum or autoclave blocks

without proper surface treatment.

✓ Not recommended over glass, wood, metal, plastic,

rubber, painted and other unsound surfaces.

✓ Do not use to bond glass mosaic or very large

format tiles.

Mixing

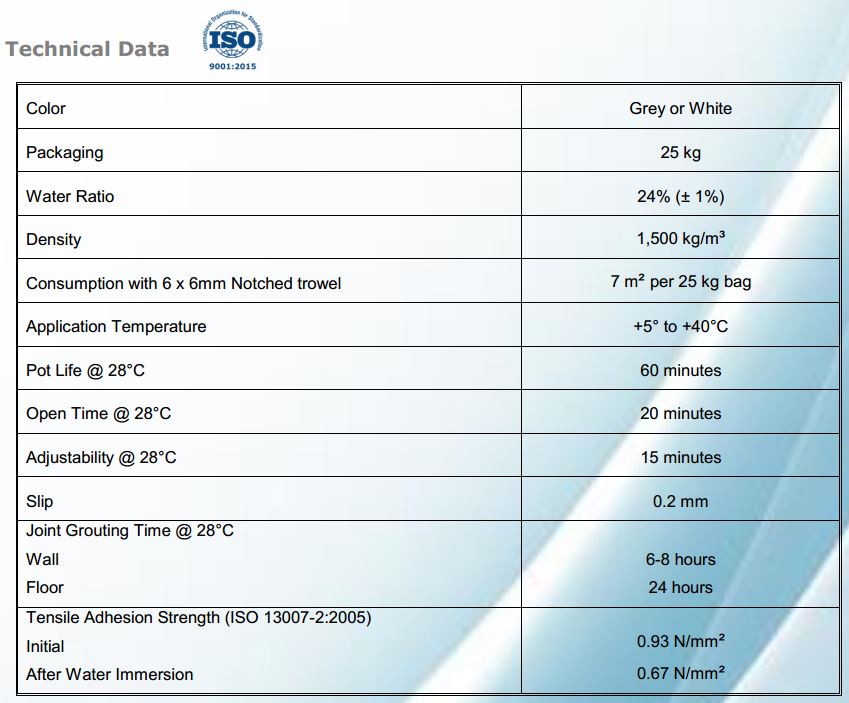

• Maxcrete 800 : 25 kg

• Clean Water : 5.75 – 6.25 liter

Pour 5.75 liter of water into mixing container and slowly add Maxcrete 800 powder while stirring with an electrical

mixer. Adjust to the desired consistency by adding part portion of 0.5 liter water. Mix for 3 minutes until lump free

homogenous consistency. Let the mix sit for 5 to 10 minutes and remix again before using.

Preparation

Concrete, screed and render shall be sufficiently cured for 28, 14 and 7 days respectively.

All substrate shall be clean, sound and free from contaminants, laitance and loose particles.

Smooth and painted surface must be scrabbled to expose at least 75% of clean roughen surface.

Expansion joints must be incorporated during the design stage to coincide with the tile joints.

Dampen the substrate prior to application.

Application

The size of notched trowel to use depends on tile sizes, depth of lugs and the evenness of the substrate. Optimal

performance is achieved with 100% coverage to both substrate and tile with a 2 to 5mm mortar bedding in

between.

With an appropriate size notched trowel, spread the mortar onto the substrate using the flat side to obtain a thin

uniform layer. Follow up by using the notched side to apply additional mortar to achieve the desired toothed

thickness. Trowel only in straight lines in a single direction.

Back butter irregular backed tiles and place the tile by moving it in back and forth motion perpendicular to the

trowel ridges.

Do not pre-soak tiles before installation. If tiles are dusty, wipe with a clean wet cloth or quick dip in clean water.

The open time of the mortar could drastically be reduced depending on conditions such as strong sunlight, dry

wind, high temperature and highly absorbent substrates.

Check constantly to see if the adhesive has formed a skin. Once skinning is detected, the adhesive must be

removed and remix. Do not add water during remix.

Do not adjust tiles after they have been placed past 15 minutes.

Wall tile joints can be grouted 6 to 8 hours after installation. Floor joint can be grouted after 24 hours.

Storage & Shelf Life

Keep elevated in dry, moisture free condition. Can be stored for 12 months in sealed original packaging.

Health & Safety

Prevent contact with skin and wear waterproof gloves and googles when handling. Upon contact with skin, wash

with soap and water. In case of eye contact, flush with water and seek medical attention immediately.